Possible causes and solutions for inconsistent shrinkage of zirconia ceramics

2024-11-18(81) Views

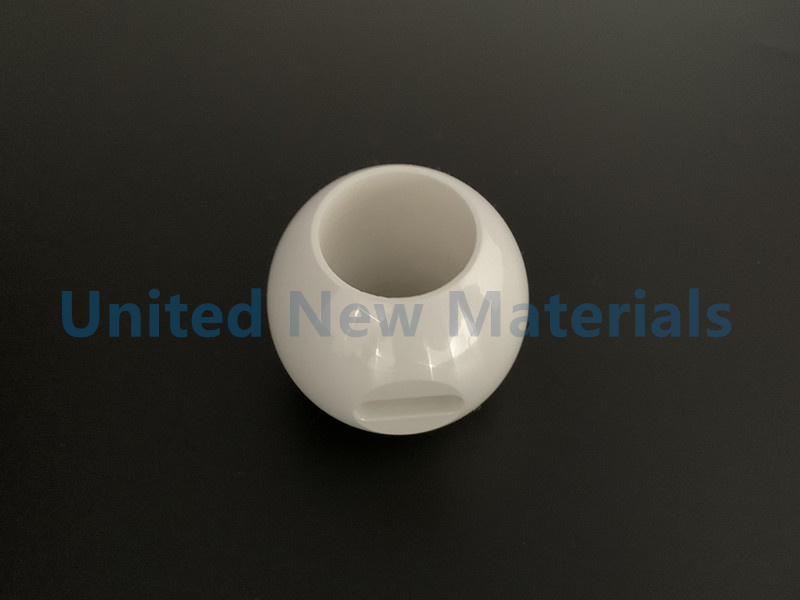

Zirconia ceramic is a new type of high-tech ceramic. It has the advantages of high strength, high hardness, high toughness, high wear resistance, high temperature resistance, acid and alkali corrosion resistance, and excellent thermal insulation properties. It is widely used in various applications. field. However, the finished zirconia ceramics we see all need to go through the sintering process. During the sintering process, due to various reasons, the shrinkage of the zirconia ceramics sometimes occurs inconsistently. So do you know what are the possible causes of inconsistent shrinkage of zirconia ceramics? And how to solve it? The following editor will introduce to you:

Possible reasons for inconsistent shrinkage of zirconia ceramics:

1. The furnace temperature is uneven and the zirconia ceramic body shrinks inconsistently.

2. The heating rate is fast, and temperature conduction creates a gradient. The closer the zirconia ceramic body is to the surface, the faster it shrinks, and the closer it is to the center, the slower it shrinks.

3. There is a density gradient. During molding, the internal shrinkage ratio of the zirconia ceramic body is inconsistent due to factors such as pressure and fillers.

Solutions to inconsistent shrinkage of zirconia ceramics:

1. Control the furnace temperature to keep the temperature of the zirconia ceramics in a uniform state.

2. During the sintering process of zirconia ceramics, attention should be paid to the heating rate to avoid excessive heating.

3. When molding zirconia ceramics, special attention must be paid to the control of density gradient, so as to better ensure a consistent shrinkage ratio within the green body. In sum

+MoreRelated Recommendations

-

What factors are related to the low friction coefficient of zirconia ceramics?

Zirconia ceramics are a class of advanced ceramics known for···

-

Zirconia ceramics always crack during processing, how to solve it?

As we all know, zirconia ceramic processing is a special cer···

-

What is the process flow of zirconia ceramic injection molding?

Among the many molding technologies for zirconia ceramics, i···

-

Possible causes and solutions for inconsistent shrinkage of zirconia ceramics

Zirconia ceramic is a new type of high-tech ceramic. It has ···

-

What significance do zirconia ceramic tools have for the cutting industry?

Nowadays, more and more consumers are choosing ceramic knive···

-

What are the characteristics of high-purity alumina semiconductor ceramics?

In recent years, with the adjustment of national policies, t···

189-1262-5805

Service Hotline:189-1262-5805

Contact Tel:189-1262-5805

Company Address:No. 78, Chang'an Road, Wujiang District, Suzhou City, Jiangsu Province (Jiufu Pioneer Park)

189-1262-5805

189-1262-5805