What is the process flow of zirconia ceramic injection molding?

2024-11-18(80) Views

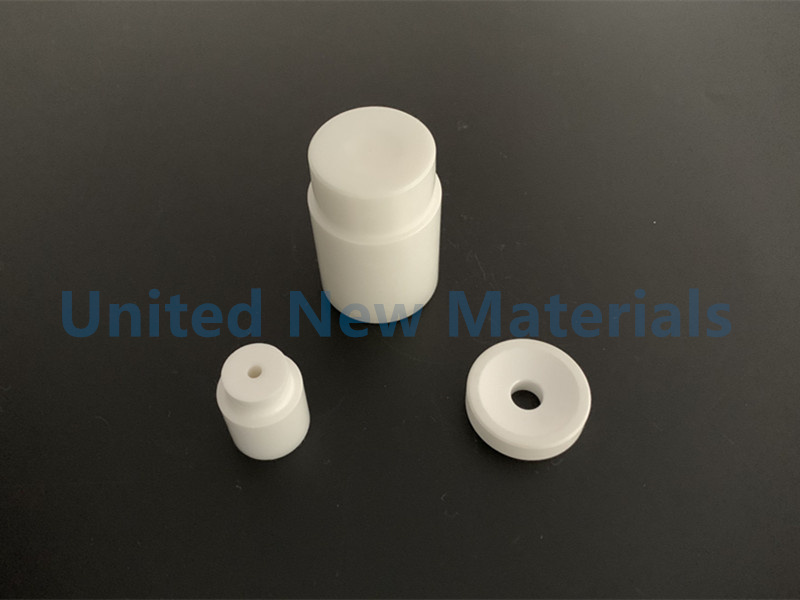

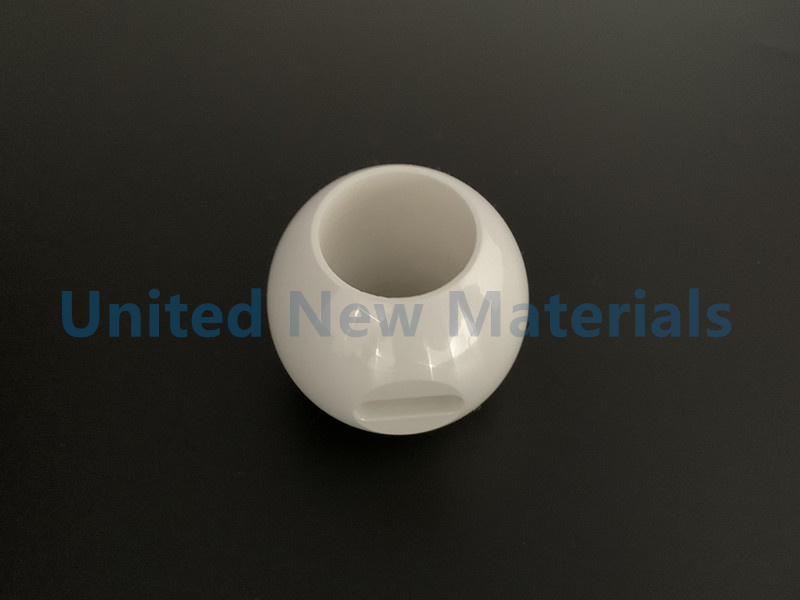

Among the many molding technologies for zirconia ceramics, injection molding technology is one of the high-precision and high-efficiency molding methods among existing ceramic molding technologies. This technology is suitable for preparing wet blanks with high strength, high dimensional accuracy of zirconia ceramics, and less mechanical processing. , a product with a uniform body, suitable for mass production. It has significant advantages in the preparation of products with complex shapes and thin thickness. So do you know what the zirconia ceramic injection molding process is? The following editor will introduce it to you:

Zirconia ceramic injection molding process flow:

1.Selection of ceramic powder The characteristics of ceramic powder, such as particle morphology, particle size distribution, average particle size, specific surface and surface free energy, etc., have an impact on other aspects of the entire zirconia ceramic injection molding process. Great impact.

2. Selection of binder The binder can fill the powder into the desired shape, and it has an important impact on the entire zirconia ceramic injection molding process.

3. Uniform mixing of ceramic powder and binder In zirconia ceramic injection molding, mixing is the main factor to obtain a uniform mixture. The mixing process involves the mass transfer of individual components to achieve a desired spatial ordering. The primary mechanism of any mixing process is the transfer mechanism.

4. Injection molding Injection molding refers to a process in which the pellets are heated and softened by an injection molding machine and then injected into a mold, where the

+MoreRelated Recommendations

-

What factors are easily affected by the performance of zirconia ceramic products?

In the ceramic equipment industry, zirconia ceramics have be···

-

Zirconia ceramics always crack during processing, how to solve it?

As we all know, zirconia ceramic processing is a special cer···

-

What factors are related to the low friction coefficient of zirconia ceramics?

Zirconia ceramics are a class of advanced ceramics known for···

-

What is the process flow of zirconia ceramic injection molding?

Among the many molding technologies for zirconia ceramics, i···

-

Possible causes and solutions for inconsistent shrinkage of zirconia ceramics

Zirconia ceramic is a new type of high-tech ceramic. It has ···

-

What significance do zirconia ceramic tools have for the cutting industry?

Nowadays, more and more consumers are choosing ceramic knive···

189-1262-5805

Service Hotline:189-1262-5805

Contact Tel:189-1262-5805

Company Address:No. 78, Chang'an Road, Wujiang District, Suzhou City, Jiangsu Province (Jiufu Pioneer Park)

189-1262-5805

189-1262-5805